Let's keep in touch

Hello Dear Customer:

If you have any questions, please enter in the corresponding frame in your information, provide your message and we'll get back to you as soon as possible, thank you.

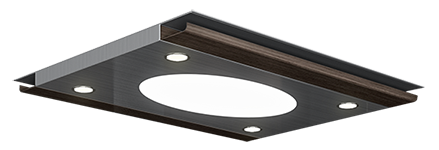

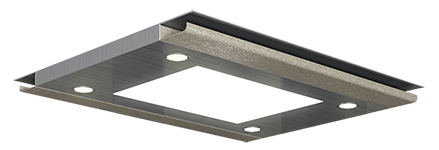

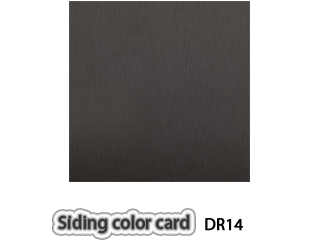

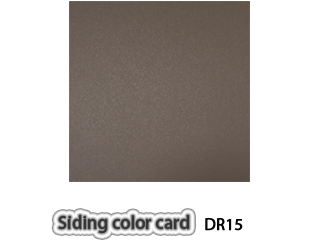

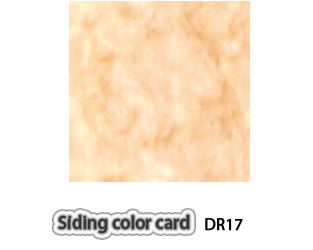

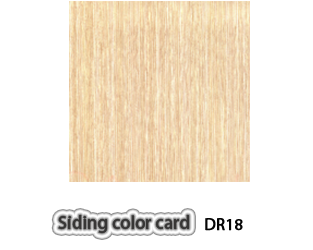

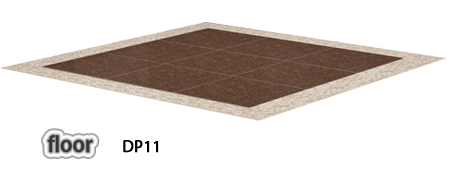

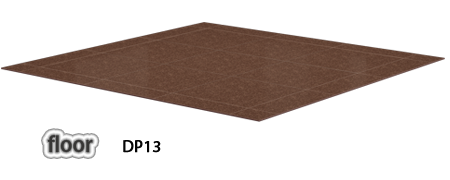

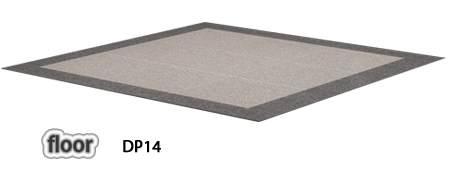

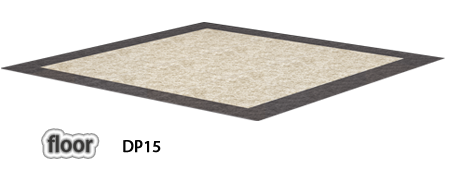

The beautiful and elegant car design, the new visual experience, the entire mirror erosion, not only the style, but also adds the modern atmosphere and exquisiteness of your elevator.

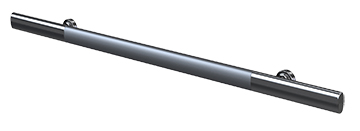

Practical equipment, hidden phone, make the appearance more beautiful and generous, intimate armrest safety measures, improve the comfort and safety of various quality certifications when riding.

The noble and elegant ride design, from the elegant home to the grand building, provides the most perfect combination, setting off the grand style of the whole building.

Pay attention to the interior space of the car, and don't neglect the feeling of the exterior of the car!

Ride design --

If the elevator is the heart of the building, then the ride is its appearance. The luxurious and comfortable ride door is not only a symbol of the building portal, but also enhances its sense of value.

When you touvh the button lightly ,

and the door opens You feel of

a warmth , elegant ,

and high qualitative elevator

~~~have an enjoyable ride~~~

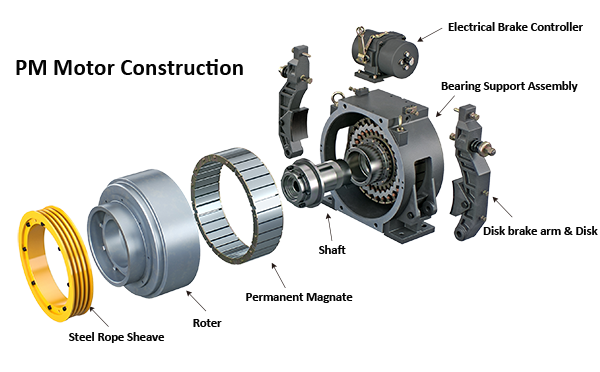

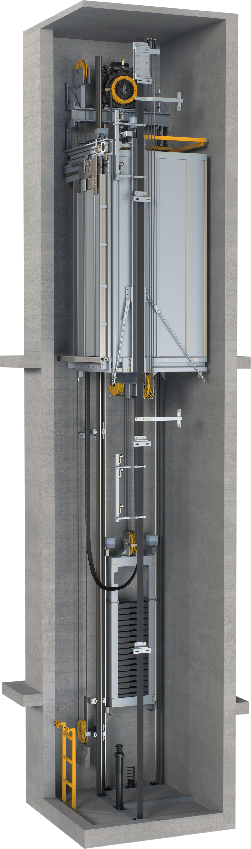

It is the abbreviation of gearless permanent magnet synchronous motor. Compared with the combination of traditional induction motor and reduction gear box, its volume is much smaller, and its high efficiency operation will be relatively energy-saving than the traditional motor. And environmentally friendly.

Permanent magnet synchronous motor replaces AC induction motor. Because it transmits torque through non-contact electromagnetic force, it solves the problem of jitter in the startup and operation of general traditional elevators, making elevators run more smoothly and more comfortably, while reducing the size of the motor. The noise is reduced, especially its energy-saving effect is very significant. If a gearless traction machine is used, when the brake of the elevator fails, the current braking function of the permanent magnet synchronous motor can be used to ensure the low-speed sliding of the car to avoid accidents, which is safe for the elevator. Add a safety barrier.

"Energy-saving" and "environmental protection" have become the clear themes of current industrial products. The current elevator design is the most different from the previous elevators, which is driven by PM permanent magnet synchronous motors.

Gear traction machine greatly improves the efficiency of operation.

When the elevator is in automatic operation and the motor decelerates to stop and open the door, if the brake that relies on the brake motor fails, the star-closing circuit is delayed by 1 to 2 seconds, the car may have moved 3 to 9 meters quickly, and it is difficult to guarantee the elevator. No personnel accidents occur.

Moreover, the life of the capacitor is aging year by year due to the influence of time and ambient temperature, and the quality is difficult to ensure.

In order to overcome the above technical defects in the industry, the company invested in R & D and improvement to replace traditional power resistors with NTC resistors.

Because the resistance value of NTC at normal temperature is large, the instantaneous high current at the time of star star short circuit is suppressed at high speed of the synchronous motor, and the NTC becomes extremely low resistance after heating, so that the synchronous motor has a large braking torque when stopped , Reduce the speed of elevator sliding, greatly improve the comfort and safety of passengers.

Unintended Car Movement Protection (UCMP), derived from the European amendment EN81-1: 1998 A3 amendment: when the elevator is in the leveling position and the door is open, if the elevator moves unexpectedly, UCMP safety Immediately start protection and stop elevator operation, adding a safety guarantee for passengers.

UCMP is aimed at motors and control systems, and can be divided into detection devices, control circuits, and brake components.

We strive to make elevator more

Safe | Comfort | Silent | Energy Efficient

PM Motor

Permanent magnet synchronous motor (PM) is characterized by its low noise and highly efficient operation. Compared to its counterpart the geared-induction motors, PM motors can save up to 30 to 40 percent of energy. Owing to these advantages, PM motors have been widely used in variety of applications.

32 Bit Processor

The 32-bit DSP based 32-bit CPU can produce space-vector modulated inverter control signal that is essential for passenger’s comfort and energy efficient. The system run fully automated tested with over a hundred advanced test items to ensure it satisfies the highest safety requirement for any situations including maximum free fall range and sudden speed up.

Safe Torque Off Operation

Safe Torque Off (STO) in used for elevator safety control that complies safety standards. It is a matured safety function found in electric vehicle design. The STO function satisfies the Drive and Motor Safety Integrity Level SIL-3 specification and resolves the contactor noise, achieving below 45dB noise level. (Note 1)

Electronic Star-sealing

State of the art “Star-sealing circuit” braking torque technology is used in PM motor drive to generate braking torque electricity generated from the load inertia in replacing traditional contactor to protect the elevator from free fall. The Start-sealing unit is designed with IGBT transistor module that do away the need for the contactor units which often produces chattering noise and contact sparks often causes malfunction of motor driver. In addition to the fast response design, electronic star-sealing can avoid instantaneous brake caused by the safety loop action during free roter movements, resulting in mechanical vibration and damages. Similar function to ABS in car braking systems. (Note 2)

UCMP Protection

Our elevators are designed in complying European Lift Safety Standard EN81-1:1998 amendment. The compliance governs two independent braking systems, self-diagnosis of braking system, door-lock loop failure detection, upward over-speed protection associated with malfunction of breaking system, and door abnormality protection. (Note 3) (Optional)

ARD Device

Automatic Rescue Device is used in case of power failure. In traditional elevator design, depends on the motor size, is equipped with 2 to 4 lead-acid rechargeable battery with 2-year service life. The star-sealing based energy regeneration system allows optimum power saving, it allows the ARD to operate with a single lithium rechargeable battery by running the motor in the light weight direction. The design consumes less than a half of the battery which extends service life up to five years and hence reduces battery maintenance costs. (Note 4) (Optional)

Automatic fault analysis:

Classification of fault categories, such as the abnormal shutdown of elevators in non-level areas, under the condition of safety and normal power supply, the system can operate at low speed to the nearest floor to open the door, reducing the incidence of closing people. The built-in clock management of the system records the fault information and the time of occurrence, which facilitates the inspection and repair of abnormal problems and accelerates the troubleshooting.

Data network system:

Combined with advanced communication technology of CANBUS and MODBUS, it has strong anti-interference, which reduces the control lines by more than 60% compared with traditional elevators, and also reduces the failures caused by abnormalities on the control lines.

Earthquake control operation:

When an earthquake of magnitude 4 or higher occurs, the "earthquake sensor" immediately sends a signal to stop the elevator on the nearest floor and open the door, so that passengers can evacuate and evacuate as soon as possible. (Optional)

Door Obstacle Protection:

In addition to the current overload protection, the elevator door detects obstacles when closing. After several door closing attempts the elevator shuts down and goes into standby mode to avoid damages.

Automatic door time:

The system selects pre-set door open time based on which call stop or destined floor to optimize traffic flow efficiency.

False call cancellation:

Passengers can cancel false calls when accidentally press the wrong floor button by pressing the same button twice.

PM synchronous motor control:

Taking the 90m / m speed on the 10th floor as an example, a general residential elevator is used as an example. The elevator runs about 4 hours a day, and it runs about 900 times. The daily power consumption of the traditional inverter induction motor is about 22 degrees (3300 yuan per month); the daily power consumption of the synchronous motor is about 15 degrees (2250 yuan per month), which saves 32% of electricity. (Including the power consumption when the elevator is semi-standby Electricity about 4 kWh per day)

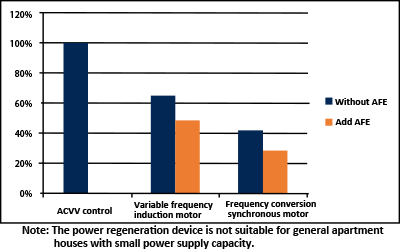

AFE power regeneration device:

When the inverter elevator decelerates and brakes, the electrical energy fed back by the motor in the form of power generation is consumed by means of the thermal energy generated by the power resistor. The high-tech energy regeneration technology can feed power back to the building power grid for other equipment. This system can save about 25-40% of energy. Most of the heat source of the elevator machine room comes from the power resistor. After installing the power regeneration device (hereinafter referred to as AFE), the resistor does not heat, and it also reduces the power consumption of the exhaust fan or air conditioner of the machine room.

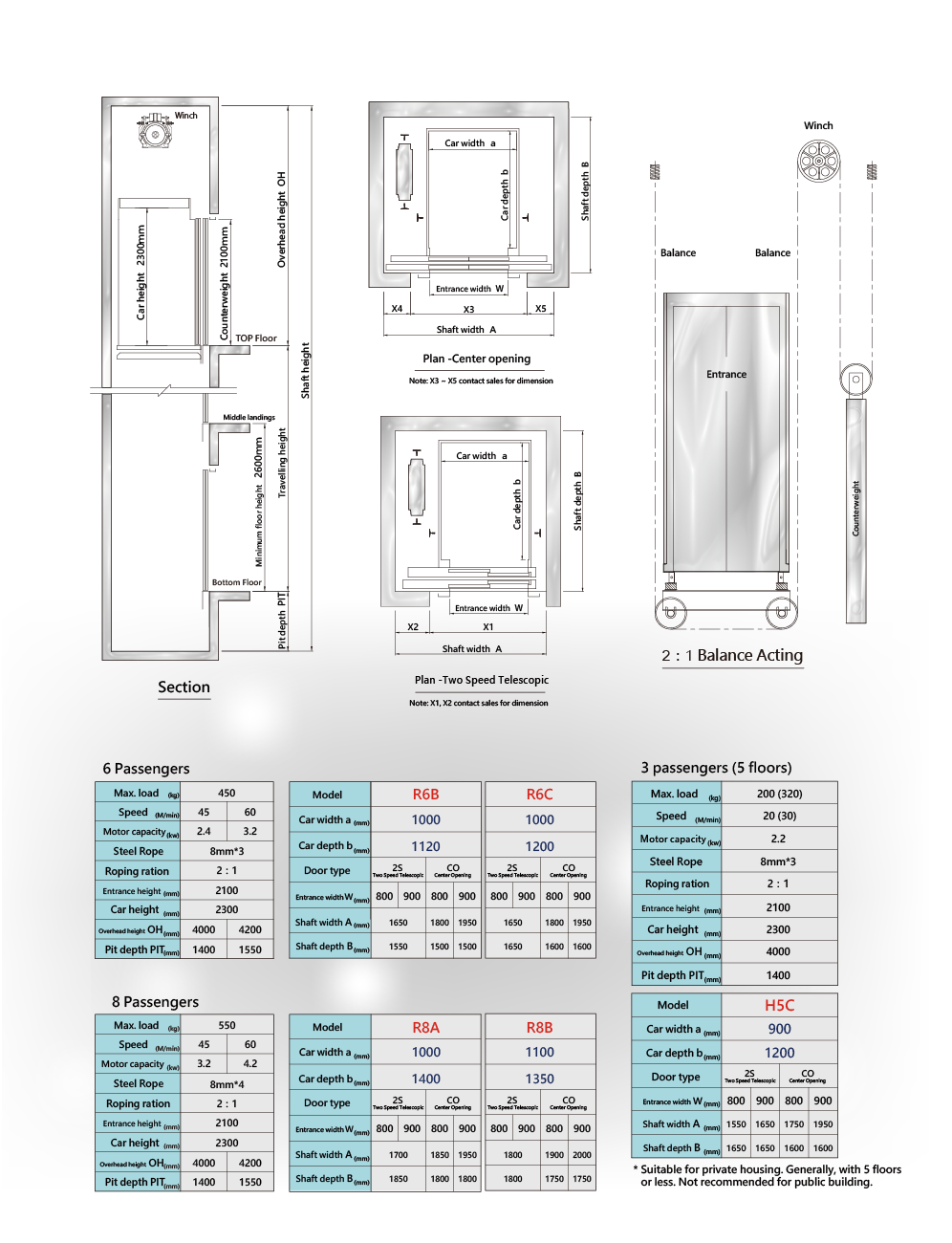

Note : All dimensions and the specifications are subject to change without notice.

Hello Dear Customer:

If you have any questions, please enter in the corresponding frame in your information, provide your message and we'll get back to you as soon as possible, thank you.